Ruthenium-iridium coated titanium anode for electrolysis of sodium chloride:

Can be applied to:

1.Electrolytic sodium hypochlorite generator

2. Chlorine dioxide generator

3. Electrolytic seawater chlorine making device

4. Swimming pool disinfection equipment

5. Electrochemical water treatment equipment

6. Electrolysis disinfection equipment, etc

Electrolytic sodium chloride principle

The chlorine gas produced at the anode reacts with OH produced at the cathode to form hypochlorite.

Selection of electrode materials for electrolysis of sodium chloride

The key of chlorine production from electrolytic salt water is the anode material used for electrolysis. In the process of electrolytic salt water, especially in the process of seawater electrolysis, due to the low concentration of sodium chloride, the anode reaction not only has chlorine evolution reaction, but also has oxygen evolution reaction. Therefore, the requirement for anode is relatively high. Titanium-based noble metal oxide anodes have been used more and more in the chlorine production industry of electrolytic salt water and seawater in recent years because of their good electrocatalytic activity and relatively low price.

Use of characteristics

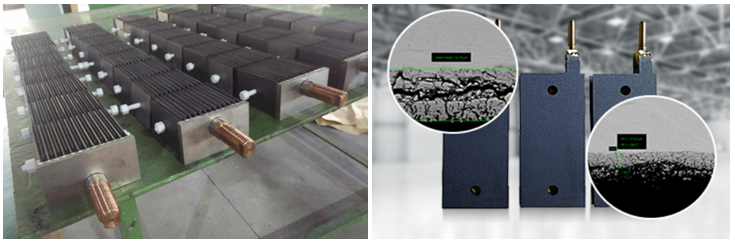

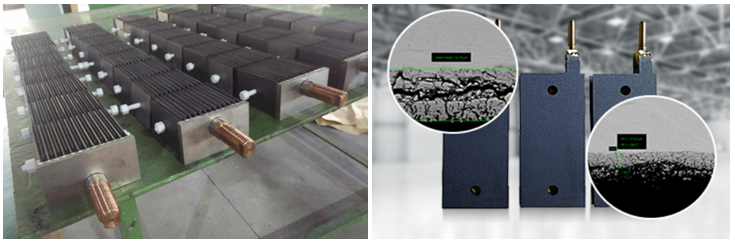

Firmakes Titanium has developed its own anode group for electrolysis and sodium chloride production of chlorine. Through continuous improvement of anode coating process and formula solvent, the nano grain is refined, the bonding strength is greatly improved, and the electrode has high electrocatalytic activity, and the electrode life is prolonged. It is suitable for the production of sodium hypochlorite, hypochloric acid and electrolysis of chlorine.

Product Parameters

The following specifications are commonly used by customers, and other specifications can be designed and customized.

| Substrate |

Coating |

Electrolyte |

Specification |

Service life |

| GR1/GR2 |

Ruthenium + multiple mixed metal oxides special formulation |

2 ~ 5.0% dilute brine or seawater access |

Conventional 50 g - 2000 g/h Or combined into larger sizes(Effective chlorine output) |

1-3Y,3-5Y,5-8Y |

Can be applied to:

1. Electrolytic sodium hypochlorite generator

2. Chlorine dioxide generator

3. Electrolytic seawater chlorine making device

4. Swimming pool disinfection equipment

5. Electrochemical water treatment equipment

6. Electrolysis disinfection equipment, etc

Our products are widely used in electrolysis, PCB, electroplating, chemical industry, environmental protection, water treatment, cathodic protection and other electrolytic anode industrial fields such as: chlor-alkali industry, chlorate production, production of hypochlorite, perchlorate, persulfate electrolysis, electrochemical organic synthesis, production of electrolytic extraction of non-ferrous metal, electrolytic silver catalyst, manufacturing electrolysis copper foil, electrolytic oxidation recycling mercury, electrolysis, chlorine dioxide production, hospital wastewater treatment, electroplating factory bearing cyanide wastewater treatment, water disinfection, power plants and food products cooling circulating water treatment, woolen mill dyeing wastewater treatment, industrial water treatment, electrolysis legal system in acid and alkaline ionized water, copper zinc plated, rhodium, palladium plating, gold plating, plating lead, electrodialysis desalination, electrodialysis method take tetramethyl ammonium hydroxide, molten salt electrolysis, battery production, cathodic protection, in the production of the cathode foil, aluminum foil anodic oxidation, etc.

Our products are exported to more than 30 countries and regions, such as Europe, America, Southeast Asia and the Middle East, etc., and have been well received and confirmed by customers. "Quality first, Customer first" is the company's service objective. We will provide customers with appropriate, environmental protection, economic high quality products.

Comments

- The company specializes in R&D, design, production and sales, and technical service of coated titanium anodes. Product categories mainly include Ru-Ir chlorine evolution titanium anodes, Ir-Ta oxygen evolution titanium anodes and platinum plating hydrogen evolution titanium anodes. There are standard and customized products; standard products include titanium tubes, titanium bars, titanium wires, titanium plates and titanium meshes and so on.

- According to different service environment, Firmakes Titanium could adjust the ratio of coating for Ir series oxygen evolution titanium anodes; improved nanoscale refined grain facilitates better combination of coating and base material to exert stronger electrocatalysis; oxygen evolution overpotential is high, amount of oxygen evolution is less, the lifespan of electrodes is long, and corrosion resistance is very good.

- Ru series coated titanium anodes have stable dimensions, electrode spacing does not change during electrolytic process, chlorine evolution overpotential is lower and corrosion resistance is good; low working voltage, high ampere density, and low power consumption with around 20% less.

- Platinum plating titanium anodes have excellent corrosion resistance; anodes could be changed in strong acid; their experiment life is 5 to 10 times as long as that of Ir-Ta electrodes; they have stable performance, suitable for various mediums.

- The company’s titanium anodes have high performance-cost ratio, good electrocatalytic activity and high efficiency of electrolysis, and could be compatible well with the environment. The base material combines very well with the coating, has excellent corrosion resistance, and could bear large ampere density.